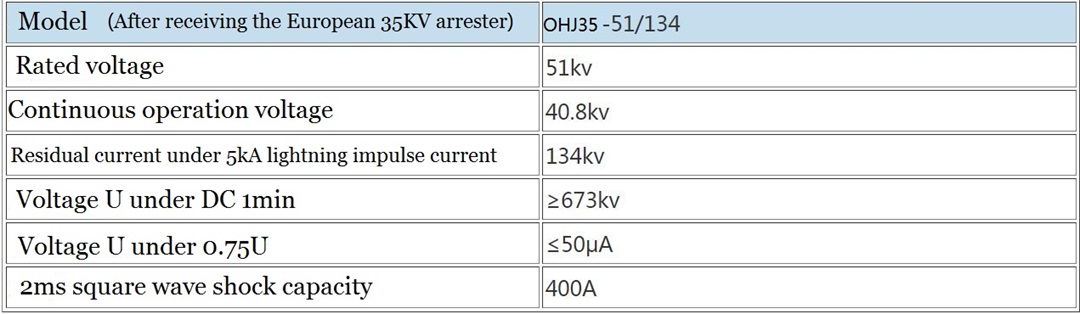

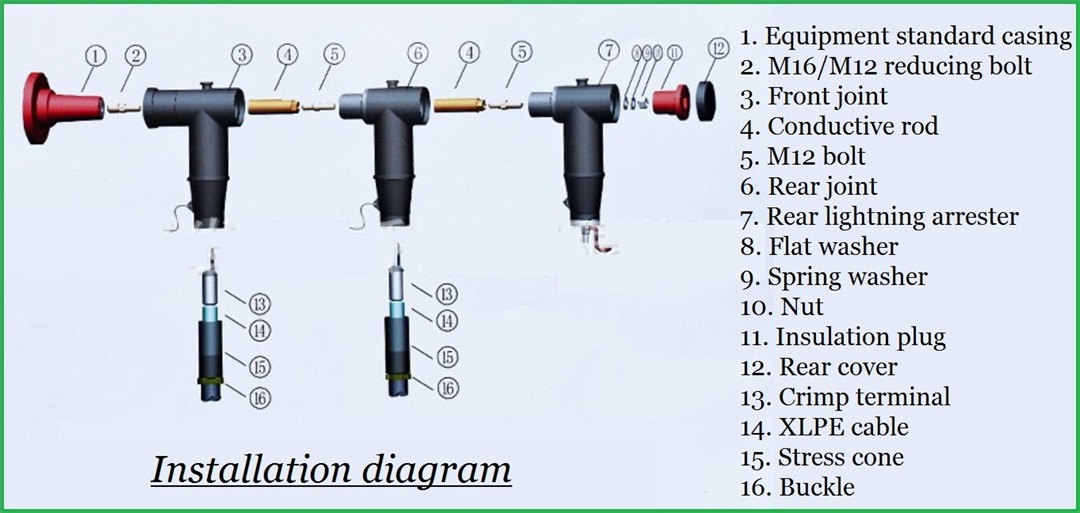

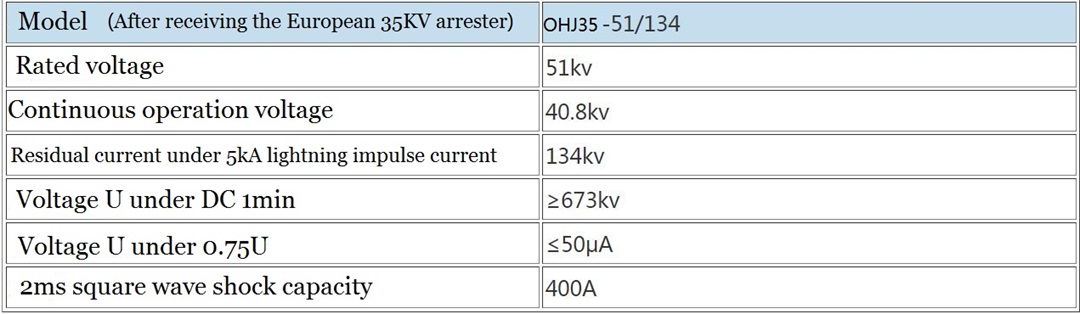

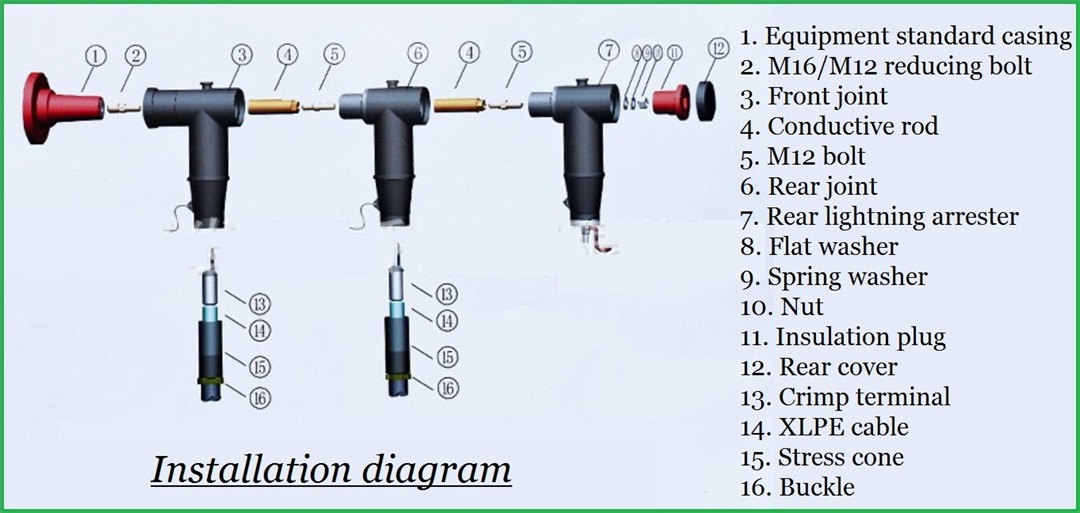

In various cable accessories, the word plug often appears next to people's ears. It is a key link to connect single-phase or three-phase cables and high-voltage switchgear, transformers, cable distribution boxes and other electrical equipment. The cable plug is easy to operate. There are n front connectors and at least one rear connector in a group of plugs, all of which are T-shaped waterproof casing structures. The structure of the T-shaped waterproof casing mentioned here is a horizontal buried hole and a direct buried hole perpendicular to each other. One group is the horizontal direction of front joint, front joint, rear joint and rear joint. The front connector is equipped with crimping terminals and crimping terminals, and the horizontal buried holes of the front power plug and rear plug are connected to mechanical equipment. Plugs, front and rear, left and right live connections are all prefabricated components in the processing plant. The access line is smart, the volume is small, the structure is compact, the equipment process is simple, and the safety factor is high. It can be used in high-voltage switch cabinets, cable branch lines and other places, and is suitable for indoor or suburban equipment. There are many simple names for cable plugs, such as elbow joints, T-joints, detachable cable terminal equipment, etc. The application rated voltage is concentrated in three categories: 10KV, 20KV and 35KV, and the application models and specifications are divided into two categories: European classical and modern American. Generally applicable to ring network power switches, high-voltage cable support boxes, ring network cabinets and other incoming and outgoing line terminal equipment and high-voltage switch cabinets with waterproof casings, which can simplify the prefabricated components and heat-shrinkable professional skills of on-site equipment. In the development trend of cable accessories occupies a dominant position. With the rapid development of my country's economic and social development, the infrastructure construction of power companies continues to increase, various commercial and residential electricity consumption continues to expand, and the field of cable accessories is also booming. As the main member of cable accessories, the plug is very important and plays a vital role in the field of power transmission and transformation projects in my country and even in the world. Elbow cable joints (referred to as elbows) are widely used in the connection of American box transformers, ring cabinets, cable branch boxes, buried transformers and other equipment. They are fully insulated and sealed plug-in terminals. Its rated current is 200A. Its conductive rod connection also has arc extinguishing function. Connected with a 200A bushing with an arc extinguishing device, it can be used as a load switch to operate a 200A current. The operation is extremely convenient. But the short-circuit current cannot be cut off. European-style plugs are also called T-connectors, or elbow plugs, detachable cable terminals or prefabricated terminal heads. The European-style plug is used in the main network system of the cable distribution box or as the inlet and outlet cable joints of the ring network cabinet. It can be connected to 600A high-voltage bushings, multi-connected combined sockets, and can also be connected to 600A busbar bushings and rear T-type Connectors are combined to form multiple cable branches. The product has an electric test head. Rated current 600A, suitable for cable cross-section 25-400mm2, suitable for Φ40/Φ52/82.3/5/8″ sockets. European-style rear-connected gapless zinc oxide arrester can be installed on electrical equipment such as box transformers, ring network cabinets, and cable branch boxes The front and back of the cable provide overvoltage protection for equipment or cables. The shielded rear surge arrester can provide reliable overvoltage protection for electrical equipment, and the molded outer shielding layer of the shielded rear surge arrester ensures the personal safety of installation and maintenance personnel The safe operation of the equipment, while its anti-ultraviolet, anti-aging, waterproof, moisture-proof, excellent performance ensures the reliable operation of the product in harsh environments.

1. Adopt full-load forming prefabricated component heat (cold) shrinkage technology and polymer material silica gel, and produce the secret recipe of tearing flame retardant for regulator. 2. Purpose: This terminal equipment is connected by shielded anchor bolts. It is suitable for ring network high-voltage switchgear, cable distribution box, European-style box transformer (chemical cross-linked power engineering cable) incoming and outgoing terminal equipment. It is connected with double-way insulation with flange casing. 3. The surface layer has a semi-conductive layer with shielding effect, which can be touched to ensure personal safety; 4. The internal stress cone structure is reasonable to fire and evacuate the internal stress of the electrostatic field, and solve the problem of cable shielding faults. 5. Scalability, smart disassembly, can complete the cable T connection; 6. Fully enclosed, fully insulating, full safety protection, maintenance-free, flood-proof, pollution-proof 7. When matched with a suitable sleeve or plug, provide full protection Shielded and fully sealed separable connection 8. It can operate under water and other harsh conditions for a long time. 9. The built-in capacitance test point is used to measure the live state of the line, and must be used in conjunction with the live display. 10. There is no requirement for a small safety distance between phases 11. The installation can be vertical, horizontal or at any angle 12. It has flame retardancy, self-extinguishing performance and excellent heat resistance; when an accident occurs in the cable accessories, it can minimize the consequences of the accident and prevent the accident to a certain extent Spreading, improving the reliability of system operation; at the same time, it has the characteristics of anti-ultraviolet, anti-oxidation, strong hydrophobic migration, non-toxic and harmless to human body, etc., suitable for special occasions and environments with serious pollution.

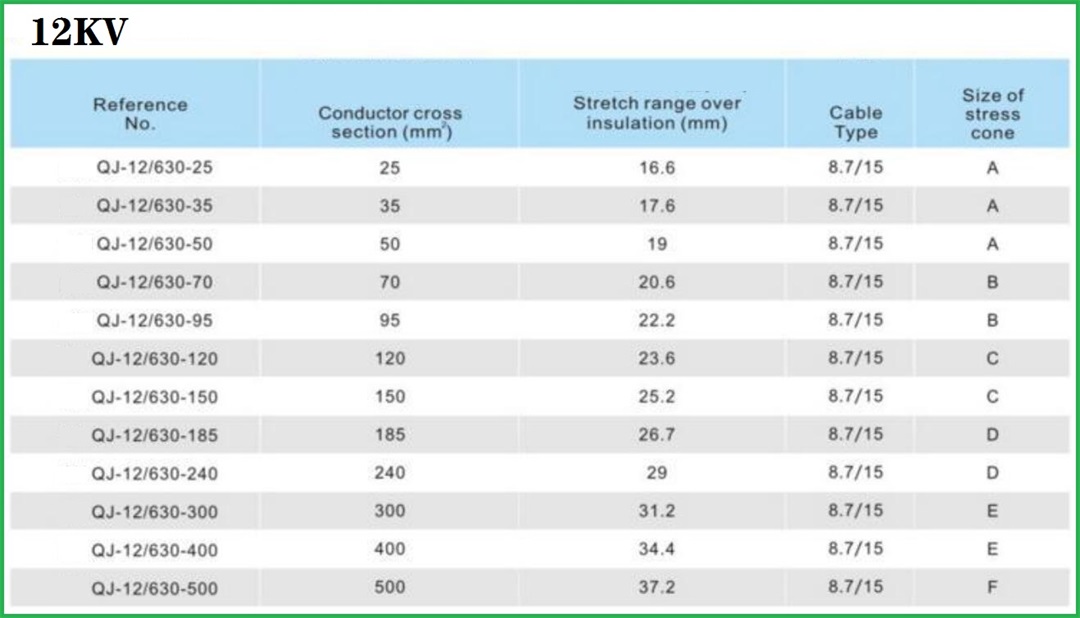

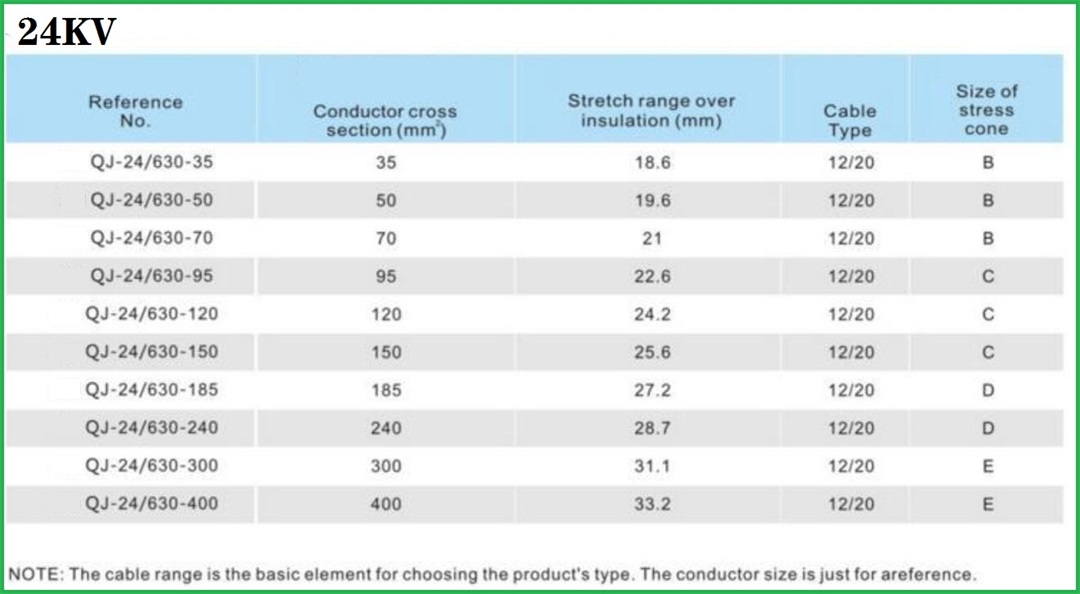

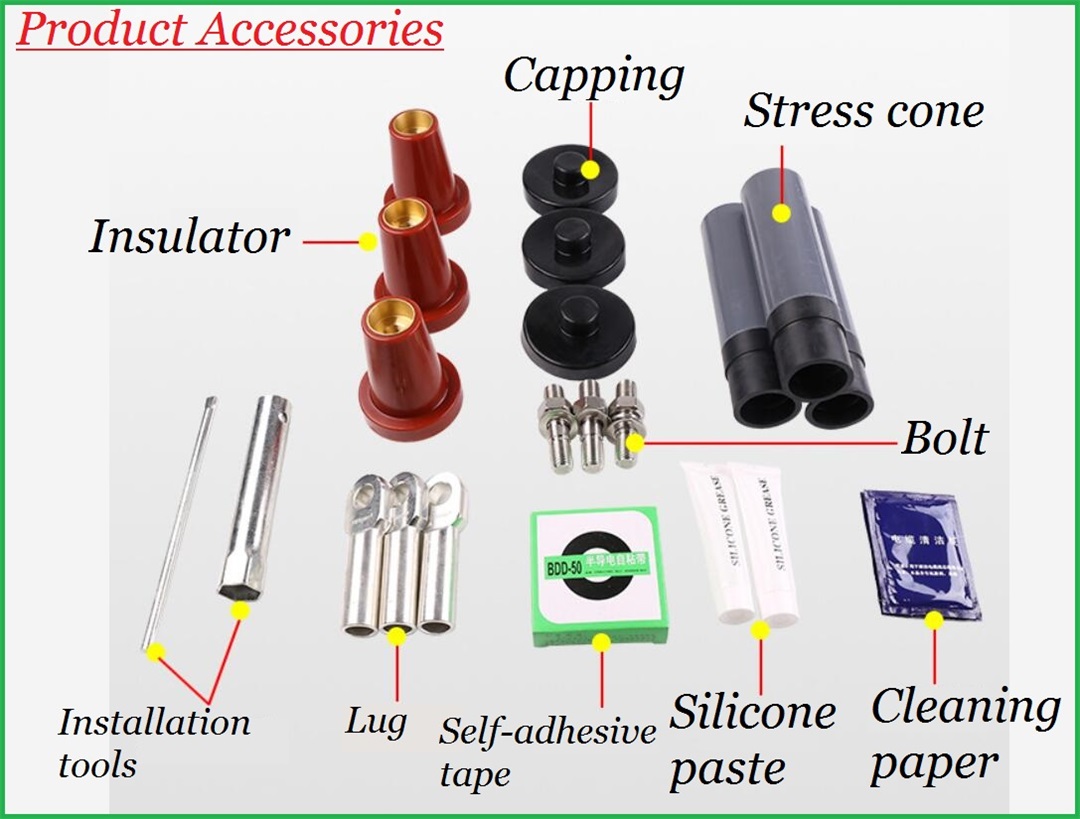

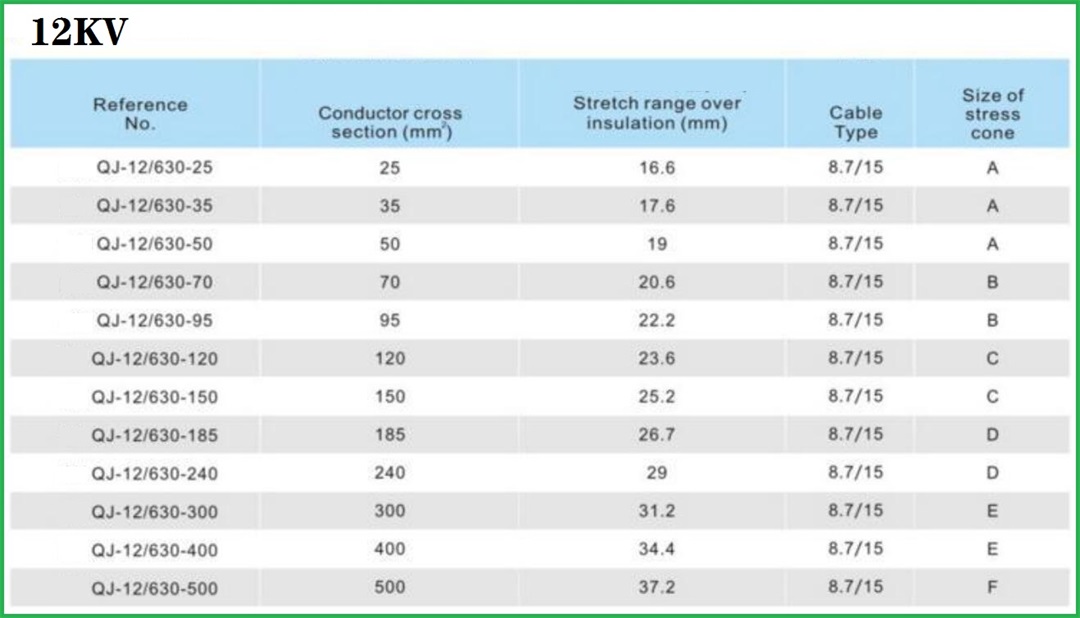

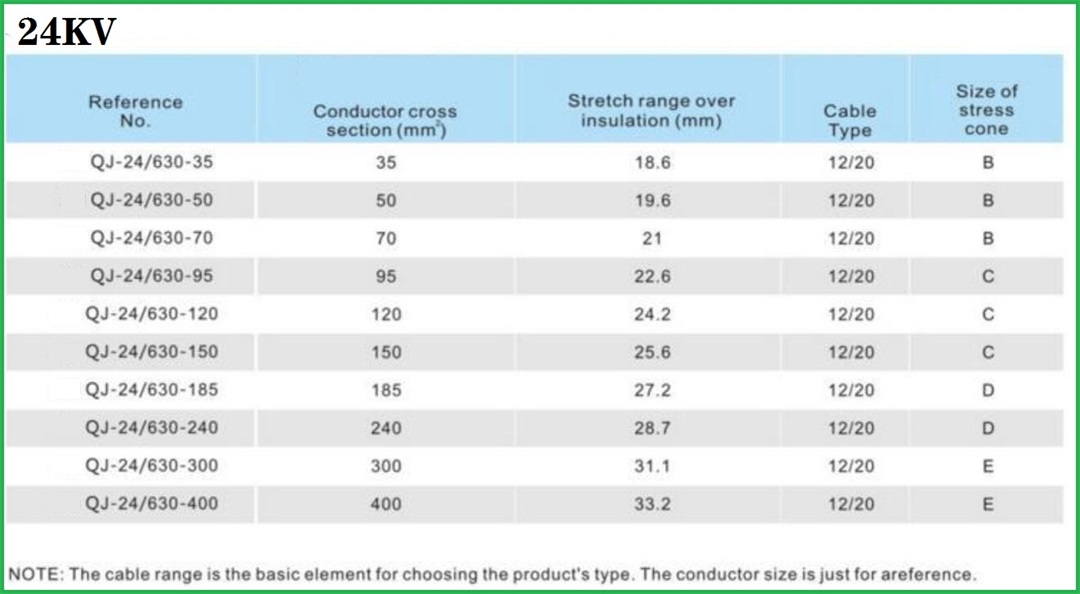

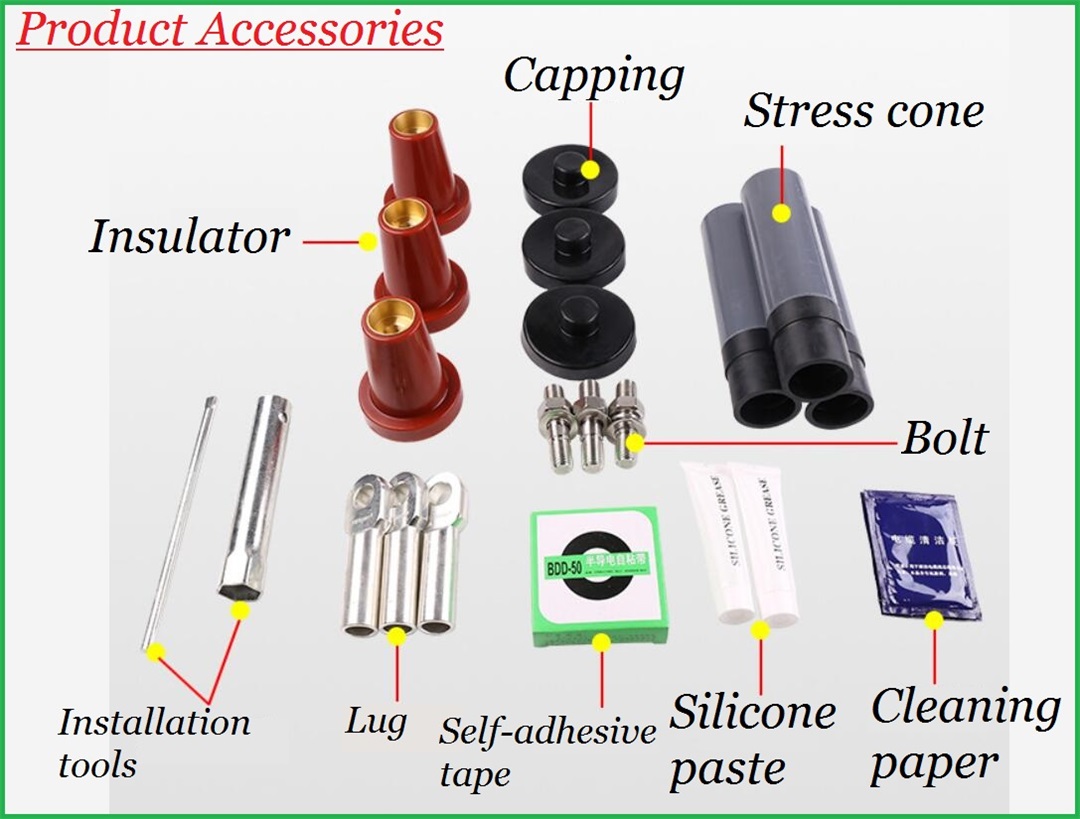

1. Stud bolt tinned copper bolt ensures tight fit between conductor and bushing 2. The unique formula and mixing technology of insulation layer ensure the quality of prefabricated EPDM insulation rubber 3. The epoxy resin insulator contains threaded metal parts to ensure close fit with stud bolts. 4. The capacitance test point is used to test whether the line is live 5. Test point cover The prefabricated EPDM conductive test point cover protects the test point and grounds it during normal operation 6. EPDM conductive rubber prefabricated with inner semiconducting layer effectively controls electrical stress 7. Stress cones of different sizes are used together with cable joints to ensure water sealing and cable stress release 8. The grounding eye is pre injected into the outer shield for the connection of the grounding wire 9. The prefabricated EPDM conductive rubber of the outer semiconducting layer is lapped with the cable shielding layer to make the shielding continuous and ensure that the outer semiconducting layer is grounded 10. Crimp terminals All copper or copper aluminum crimp terminals are suitable for copper or aluminum conductors

1. Stud bolt tinned copper bolt ensures tight fit between conductor and bushing 2. The unique formula and mixing technology of insulation layer ensure the quality of prefabricated EPDM insulation rubber 3. The epoxy resin insulator contains threaded metal parts to ensure close fit with stud bolts. 4. The capacitance test point is used to test whether the line is live 5. Test point cover The prefabricated EPDM conductive test point cover protects the test point and grounds it during normal operation 6. EPDM conductive rubber prefabricated with inner semiconducting layer effectively controls electrical stress 7. Stress cones of different sizes are used together with cable joints to ensure water sealing and cable stress release 8. The grounding eye is pre injected into the outer shield for the connection of the grounding wire 9. The prefabricated EPDM conductive rubber of the outer semiconducting layer is lapped with the cable shielding layer to make the shielding continuous and ensure that the outer semiconducting layer is grounded 10. Crimp terminals All copper or copper aluminum crimp terminals are suitable for copper or aluminum conductors

1. Stud bolt tinned copper bolt ensures tight fit between conductor and bushing 2. The unique formula and mixing technology of insulation layer ensure the quality of prefabricated EPDM insulation rubber 3. The epoxy resin insulator contains threaded metal parts to ensure close fit with stud bolts. 4. The capacitance test point is used to test whether the line is live 5. Test point cover The prefabricated EPDM conductive test point cover protects the test point and grounds it during normal operation 6. EPDM conductive rubber prefabricated with inner semiconducting layer effectively controls electrical stress 7. Stress cones of different sizes are used together with cable joints to ensure water sealing and cable stress release 8. The grounding eye is pre injected into the outer shield for the connection of the grounding wire 9. The prefabricated EPDM conductive rubber of the outer semiconducting layer is lapped with the cable shielding layer to make the shielding continuous and ensure that the outer semiconducting layer is grounded 10. Crimp terminals All copper or copper aluminum crimp terminals are suitable for copper or aluminum conductors

1. Stud bolt tinned copper bolt ensures tight fit between conductor and bushing 2. The unique formula and mixing technology of insulation layer ensure the quality of prefabricated EPDM insulation rubber 3. The epoxy resin insulator contains threaded metal parts to ensure close fit with stud bolts. 4. The capacitance test point is used to test whether the line is live 5. Test point cover The prefabricated EPDM conductive test point cover protects the test point and grounds it during normal operation 6. EPDM conductive rubber prefabricated with inner semiconducting layer effectively controls electrical stress 7. Stress cones of different sizes are used together with cable joints to ensure water sealing and cable stress release 8. The grounding eye is pre injected into the outer shield for the connection of the grounding wire 9. The prefabricated EPDM conductive rubber of the outer semiconducting layer is lapped with the cable shielding layer to make the shielding continuous and ensure that the outer semiconducting layer is grounded 10. Crimp terminals All copper or copper aluminum crimp terminals are suitable for copper or aluminum conductors